ROLL CRUSHER

DOUBLE ROLLER CRUSHER, ROCK CRUSHER, MOBILE CRUSHER, PORTABLE CRUSHER

DOVE Roll Crusher also referred to as Double Roller Crusher, or Twin Roll Crusher is highly efficient crushing machine, used in certain applications for primary, secondary and tertiary crushing applications. DOVE Roller crushers are highly practical crushers for soft to medium-hard ore and where the final crushed out put is required to be of uniform grain sizes, with minimum of fine and under size grains.

DOVE Roller Crushers are highly popular crushers in mining industry, with various advantages, such as high capacity, low horse power, low headroom, ability to handle wet ore, ability to handle sticky feed material, producing uniform crushed particle size, with minimum undersize fines, excellent reliability, and very little maintenance.

DOVE Roller Crushers are supplied in two different configurations. Flat Roller Crushers series supplied in nine models, with capacity range of (5 – 260 metric Tons/ Hour). Tooth Roller Crusher series in eight models, with capacity range of (30 –300 metric Tons/ Hour), applicable for various industries, including Mining, Metallurgy, Coal, Chemical, Biotechnology, Pharmaceutical, Construction, Aggregate, Solid Waste Treatment, etc.

FEATURES:

- DOVE Roller Crushers are configured with unique Replaceable Wear-Resistance-Liners Cover, which are fabricated with advance wear resistant material, for long service life. The replaceable wear resistance Liner cover of the rollers is easily replaceable, and low cost, which is unmatched in the industry.

- DOVE Double Roll Crushers are highly reliable and are designed with Built-In Tramp Relief capability, which is a Safety Protection module, designed to reject pieces of iron or uncrushable material, while allowing continuous crushing, with no interruption to the crushing operation.

- DOVE Roll Crushers are highly versatile, configured with easy adjustments in Rollers Speed.

- The Rollers Gap strings of the Roller Crusher is designed to be easily adjusted with the gap setting of (1 – 20 mm), in order to meet the requirements for various particles crushing sizes, and any application requirements.

- The Rollers are interconnected by coupling, which results in a long life for the Belts.

- DOVE Roll Crushers are designed with compact structure, small space installation, Light weight, Convenient operation, and low maintenance.

- DOVE Tooth Roll Crushers are supplied in eight models with large crushing capacity of up to 300 metric Tons/Hour.

- DOVE Tooth Roller Crushers are highly safe and reliable, they are configured with high quality motor and reducer, which are connected by special Spacing-Limited hydraulic coupler, in order to prevent power overload, in addition to Sensor Overload Protection capability.

- DOVE Tooth Roll Crushers are designed to allow the teeth Roller spacing to be adjusted by hydraulic pressure, and the teeth Roller Bearings are lubricated centrally.

- DOVE Tooth Roll Crushers have the highest crushing ratio in the industry, has no minimum requirements for moisture content of crushed material, no restrictions for sticking material, handle all type material efficiently.

- DOVE Tooth Roll Crushers are configured with intelligent cleaning device, to automatically remove the sticky material from the wall of the crusher.

- DOVE Roll Crushers are configured with Dust-Proof Board, which avoids splashing of small crushed material, less dust.

- DOVE Tooth Roll Crushers are designed with tungsten carbide harden tooth for increased wear life.

APPLICATIONS:

DOVE Flat Roll Crushers and DOVE Tooth Roll Crushers are highly popular crushers effectively deployed in crushing circuit for various industries, including Mining, Coal, Metallurgy, chemical industry, Building and Construction industries, Solid Waste processing, etc.

DOVE Roller crushers are highly practical crushers for soft to medium-hard ore and where the final crushed out put is required to be of uniform grain sizes, with minimum of fine and under size grains.

DOVE Tooth Roll Crushers are highly effective in crushing raw coal, including Gangue, in large coal preparation plants. Tooth Roll Crushers have larger crushing capacity than Flat Roll Crushers.

RANGE & TECHNICAL SPECIFICATIONS

| FLAT ROLL CRUSHERS | ||||||

| MODELS |

ROLLER DIAMETER | ROLLER LENGTH | MAX INPUT SIZE | CAPACITY | DISCHARGE SIZE | MOTOR POWER |

| (mm) | (mm) | (mm) | (TONNES/HOUR) | (mm) | (kW) | |

| FRC2-10 | 400 | 250 | <25 | 5 – 10 | 1 – 8 | 5.5 x 2 |

| FRC2-20 | 610 | 400 | <25 | 10 – 20 | 2 – 20 | 18.5 x 2 |

| FRC2-30 | 750 | 500 | <25 | 15 – 30 | 2 – 25 | 22 x 2 |

| FRC2-40 | 800 | 600 | <80 | 20 – 40 | 3 – 25 | 30 x 2 |

| FRC2-50 | 1,000 | 800 | <100 | 30 – 50 | 3 – 30 | 45 x 2 |

| FRC2-70 | 1,200 | 800 | <120 | 40 – 70 | 3 – 35 | 110 x 2 |

| FRC2-110 | 1,200 | 1,000 | <120 | 60 – 110 | 3 – 40 | 110 x 2 |

| FRC2-180 | 1,500 | 1,200 | <130 | 100-180 | 3 – 45 | 160 x 2 |

| FRC2-260 | 1,800 | 1,500 | <160 | 160-260 | 3 – 55 | 220 x 2 |

| TOOTH ROLL CRUSHERS | ||||||

| MODELS |

ROLLER DIAMETER | ROLLER LENGTH | MAX. INPUT SIZE | CAPACITY | DISCHARGE SIZE | MOTOR POWER |

| (mm) | (mm) | (mm) | (TONNES/HOUR) | (mm) | (kW) | |

| TRC2-50 | 450 | 500 | 200 – 500 | 30 – 50 | 25 – 125 | 5.5 x 2 |

| TRC2-60 | 600 | 500 | 200 – 500 | 40 – 60 | 25 – 125 | 7.5 x 2 |

| TRC2-100 | 600 | 750 | 300 – 600 | 60 – 100 | 30 – 150 | 11 x 2 |

| TRC2-120 | 600 | 900 | 300 – 600 | 80 – 120 | 30 – 150 | 18.5 x 2 |

| TRC2-160 | 800 | 1050 | 500 – 800 | 100 – 160 | 30 – 150 | 22 x 2 |

| TRC2-200 | 900 | 900 | 600 – 900 | 150 – 200 | 30 – 200 | 22 x 2 |

| TRC2-250 | 1,015 | 760 | 700 – 950 | 200 – 250 | 30 – 200 | 45 x 2 |

| TRC2-300 | 1,200 | 1,500 | 250 – 300 | 250 – 300 | 30 – 200 | 55 x 2 |

* DOVE reserves the right to modify the specifications at anytime, without prior notice.

WARRANTY:

All DOVE equipment carry a standard Manufacturer’s Warranty, which can be extended to 5 years, in addition to lifetime spare parts supply service.

DOVE provides full technical services worldwide, including plant engineering design, mining site construction design, site assembly, installation, test run and training.

MANUFACTURING FACILITIES:

DOVE Equipment & Machinery manufacturing facilities are located about 30 minutes drive from the company Head office in Bangkok, which includes 8 factories and showroom.

DOVE Equipment and Machinery with over 50 years manufacturing expertise, and the largest range of mining and minerals processing technologies is the recipient of ISO 9001: 2015, Green Industry Certification, and Golden Eagle of Asia Awards 2020 Best Business of the Year (DOVE Equipment and Machinery and DOVE Instruments), which insures highest quality and standard of our manufacturing and customer service practices.

DOVE Manufacturing Facilities.

DOVE Equipment and Machinery 8 Factories.

Video of DOVE Manufacturing Facilities:

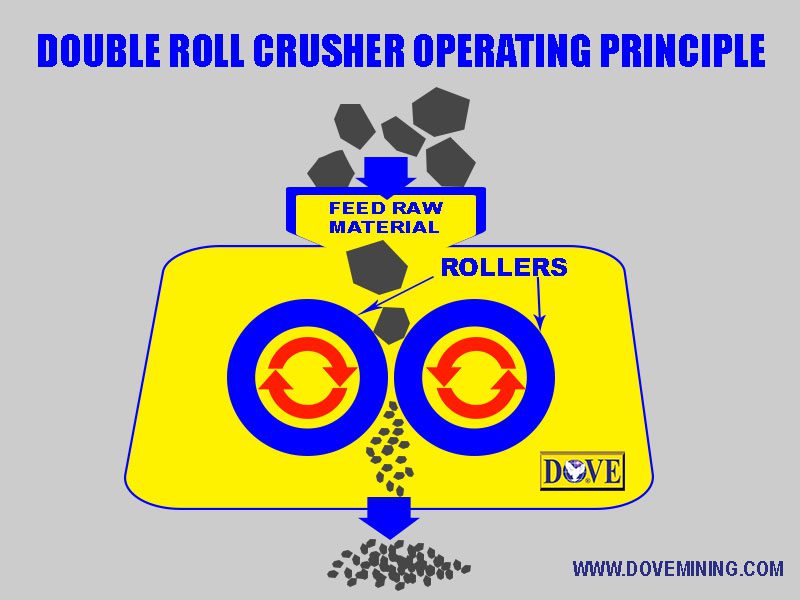

ROLL CRUSHER OPERATING PRINCIPLE:

DOVE Roll Crushers operates and perform particle crushing and size reduction, based on principal of Impact, shear and compression. The Crusher is composed of a feed hopper, where the material enters the Crusher, two Rolls rotating in opposite directions, connected to a shaft. The material to be crushed fall from the feeding hopper to the Gap between the two Rollers, where the impact force occurs as the material enters the Gap between the Rollers and is impacted by the rotating Rollers. Subsequently, Shear and compression forces occur as the feed material further moves between the crushing Rollers.

The Gap between the Rollers is set to the size of the final desired product. The feed particles entering the crusher are drawn into the Gap between the Rollers by the Rollers rotating motion and the friction angle formed in the Gap, between the Rollers and particles entering the Gap. This is referred to as Nip Angle. As the rollers draw the feed particles between the rotating Rollers, the Gap and the Nip Angle become smaller, which results in feed particles to fracture from the Compressive force presented by the rotating Rollers.

The Feed material to be crushed, once pass through the feed hopper falls through the Gap between the Rollers and once the material crushed the final crushed material fall below the Gap to exit the Crusher. In the event accidentally too hard material, or material which cannot be crushed is mixed with the original feed and enters the Gap between the Rollers, The Crusher will spit out the hard material. This safety mechanism is based on the bearing of the movable roller, which allow the Roller to move along the frame and supported by a strong safety spring.

Roll Crusher can be configured with a single roller, which is designed to crush material between a rotating roller and a crushing plate, or double rotating rollers. In the event the application requires two stages crushing, a triple or quad roll configuration can be provided. In the event of triple or quad roll configuration, the top single roller, or double rollers perform the primary crushing function, and the lower rollers shall perform the secondary crushing and material size reduction.

Tooth Roll Crushers motor and reducer are connected by a spring limited hydraulic coupler to prevent power overload and sensor overload protection. The teeth roller spacing is adjusted by hydraulic pressure. The teeth roller bearings are lubricated centrally.

WE HIGHLY RECOMMEND FORWARDING SOIL SAMPLES OF YOUR MINE TO US FOR ANALYSIS, IN ORDER TO DESIGN AND RECOMMEND THE MOST EFFICIENT PROCESSING PLANT, TAILOR MAID TO YOUR MINE REQUIREMENTS, FOR HIGHEST PRODUCTION RECOVERY.