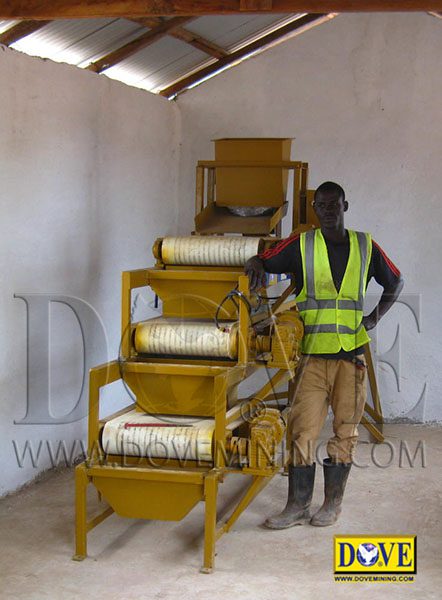

HIGH INTENSITY MAGNETIC ROLLER SEPARATOR

DOVE High Intensity Magnetic Roller is a highly efficient and economical magnetic separator, designed for rapid and precise separation of dry fine and coarse granular mixture of magnetic from non magnetic and weakly magnetic materials.

DOVE Magnetic Roller is highly effective means of Purifying and upgrading ferrous minerals and efficiently separate magnetic, as well as weakly magnetic minerals from non magnetic elements.

The process of purifying and cleaning various types of material utilizing magnetic process is the most effective, practical and economical technology applied to Industrial minerals industry, metals recycling, Abrasives, Glass batch, Cullet,, Chemicals, Pharmaceuticals, Refractories, and Plastic industries.

DOVE MAGNETIC ROLLER SEPARATOR FEATURES:

- Dry magnetic Roller is supplied as a complete system, it includes Feed Hopper and Vibrating Feeder.

- The Roller is supplied in 12 models, with feed capacity range of 1.5 Tons/Hour, up to 7.5 Tons/hour.

- DOVE Magnetic Roller is supplied with optional 1, 2, 3, or 4 Roller Drums, with powerful 15,000 Gauss Magnetic Intensity.

- Magnetic Roller Separator is highly economical, very low in in initial investment and also low in power usage (0.75 – 2.2 kW), and extremely low maintenance, System is designed for either manual or inline feed for continuous processing and separation of minerals.

- DOVE Magnetic Roller is designed for continuous and effective separation of 0.5 – 5.0 mm (0.0199 – 0.197 Inch).

- Magnetic Roller speed is adjustable, allowing wider particle size and yield.

- The material feeding system is controlled, therefore it allows homogeneous material flow through the roller magnetic field, which results in standard quality of separation, cleaning and purified material.

- The roller is supplied with special quality belt, produced from special quality of material, for long life and minimum wear resistance.

- High Intensity Magnetic Roller is designed and manufactured with alloys of Rare Earth mineral elements and more powerful than other magnets and are permanent magnets.

- DOVE High Intensity Magnetic Roller is the most advance roller in the industry, fully designed to meet environmental consideration, designed with dust removal module and concentrated dust emission.

DOVE Magnietic Roller operation video:

APPLICATIONS:

DOVE High Gradient Magnetic Roller, also referred to as magnetic roller separator, or dry high intensity rare earth magnetic roller, is the most advanced magnetic separator, designed and engineered for optimum performance, in various applications and industries.

- Separation or Purifying the coarse weakly magnetic material, such as Hematite, Ilmenite, Manganese, etc.

- Reduce and separate the content of ferrous contaminants in non magnetic material.

- Increase concentration of non ferrous material, such as quartz, Feldspar, Andalusite, etc.

- Separation and cleanup of ferrous impurities from abrasives, catalysts, etc.

- Separation of magnetic elements of rare earth from non magnetic and weakly magnetic elements.

- Separation of Silica sand, Quartz, Carbide, Chromite Recovery, Graphite Recovery, Graphite upgrading, Alumina, Abrasive and refractory, Magnesite beneficiation.

- Copper – Nickel ore pre concentration, Manganese and Glass sand beneficiation, Andalusite and Pyrophyllite beneficiation, Diatomaccous earth cleaning and Kyanite cleaning.

- Iron ore beneficiation, Diamond beneficiation, Feldspar, Dolomite, Glass raw materials cleaning, Wollastonite beneficiation, Bauxite cleaning, Magnesite cleaning, Feldspar cleaning, Bauxite upgrading.

- Recovery of metals from slag, Ceramic raw material cleaning, Metal value recovery from waste, Quarts ultra high cleaning, Flint clay and Graphite beneficiation.

- Removal of Ferro Silicates from Limestone Magnesite, Separation and recovery of Garnet, Ilmenite, Rutile, and Zircon.

RANGE AND TECHNICAL SPECIFICATIONS

| MODEL | CAPACITY (TPH) | NUMBER OF ROLLERS | MAGNETIC ROLL DIAMETER (mm) | MAGNETIC LENGTH (mm) | MAGNETIC INTENSITY (GAUSS) | FEED FRACTION (mm) | FEED POWER (kW) | MOTOR POWER (kW) |

| RMS3 – R1 | 1.5 – 3 | 1 | 220 | 500 | 15000 | 0.5 – 5 | 0.22 | 0.75 |

| RMS3 – R2 | 1.5 – 3 | 2 | 220 | 500 | 15000 | 0.5 – 5 | 0.22 | 0.75 |

| RMS3 – R3 | 1.5 – 3 | 3 | 220 | 500 | 15000 | 0.5 – 5 | 0.22 | 0.75 |

| RMS3 – R4 | 1.5 – 3 | 4 | 220 | 500 | 15000 | 0.5 – 5 | 0.22 | 0.75 |

| RMS5 – R1 | 4 – 5 | 1 | 220 | 1000 | 15000 | 0.5 – 5 | 0.22 | 1.5 |

| RMS5 – R2 | 4 – 5 | 2 | 220 | 1000 | 15000 | 0.5 – 5 | 0.22 | 1.5 |

| RMS5 – R3 | 4 -5 | 3 | 220 | 1000 | 15000 | 0.5 – 5 | 0.22 | 1.5 |

| RMS5 – R4 | 4 – 5 | 4 | 220 | 1000 | 15000 | 0.5 – 5 | 0.22 | 1.5 |

| RMS8 – R1 | 6.5 – 7.5 | 1 | 220 | 1500 | 15000 | 0.5 – 5 | 0.22 | 2.2 |

| RMS8 – R2 | 6.5 – 7.5 | 2 | 220 | 1500 | 15000 | 0.5 – 5 | 0.22 | 2.2 |

| RMS8 – R3 | 6.5 – 7.5 | 3 | 220 | 1500 | 15000 | 0.5 – 5 | 0.22 | 2.2 |

| RMS8 – R4 | 6.5 – 7.5 | 4 | 220 | 1500 | 15000 | 0.5 – 5 | 0.22 | 2.2 |

WARRANTY:

All DOVE equipment carry a standard Manufacturer’s Warranty, which can be extended to 5 years, in addition to lifetime spare parts supply service.

DOVE provides full technical services worldwide, including plant engineering design, mining site construction design, site assembly, installation, test run and training.

MANUFACTURING FACILITIES:

DOVE Equipment & Machinery manufacturing facilities are located about 30 minutes drive from the company Head office in Bangkok, which includes 8 factories and showroom.

DOVE Equipment and Machinery with over 50 years manufacturing expertise, and the largest range of mining and minerals processing technologies is the recipient of ISO 9001: 2015, Green Industry Certification, and Golden Eagle of Asia Awards 2020 Best Business of the Year (DOVE Equipment and Machinery and DOVE Instruments), which insures highest quality and standard of our manufacturing and customer service practices.

DOVE Manufacturing Facilities.

DOVE Equipment and Machinery 8 Factories.

Video of DOVE Manufacturing Facilities:

MINERAL TEST SERVICES:

DOVE laboratory will assay your ore samples rapidly and analyze your raw materials and recommend the most efficient processing plant according to the ore specifications, minerals composition, and ore assay results, and your project size and the geologic and topographic conditions of your mine.

Please, CONTACT US for your sample analysis and quotation.

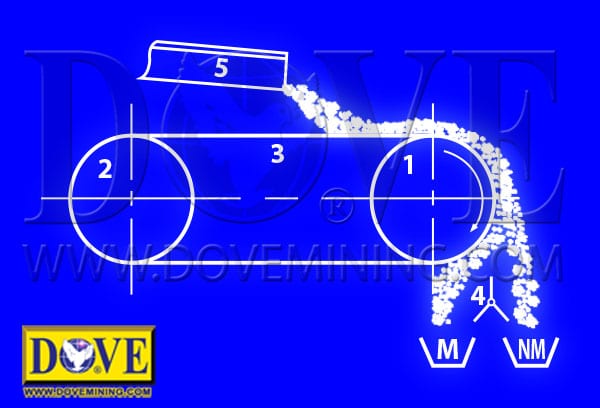

HIGH INTENSITY MAGNETIC ROLLER SEPARATOR OPERATING PRINCIPLE:

The Ore or material are feed to the Hopper of the Magnetic Roller either manually or by conveyer belt or other inline continuous feeding mechanism. Material go through the feed hopper and feed to the Magnetic Roller by the Vibrating Feeder.

Vibrating Feeder on continuous basis on the wide angel feed the material to the Rotating belt, which carries the material into the magnetic field of the Roller. Magnetic particles are attracted by the magnet and discharged, soon as the belt moves and reaches the non magnetic field. Up on clearing this step, the magnetic particles move to the next stage for clean and upgrade ferrous material, or move to the magnetic bucket. Subsequently the non magnetic move to the next stage for clean.

WE HIGHLY RECOMMEND FORWARDING SOIL SAMPLES OF YOUR MINE TO US FOR ANALYSIS, IN ORDER TO DESIGN AND RECOMMEND THE MOST EFFICIENT PROCESSING PLANT, TAILOR MAID TO YOUR MINE REQUIREMENTS, FOR HIGHEST PRODUCTION RECOVERY.