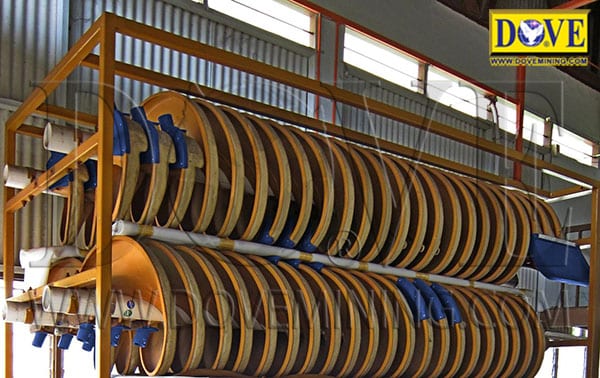

SPIRAL CONCENTRATORS

HEAVY MINERAL SPIRAL CONCENTRATORS

DOVE Spiral Concentrators are cost-effective, high performance gravity concentration separators used for separation and recovery of a wide range of heavy minerals: hematite, zircon, ilmenite, rutile, iron ore, chromite, coal, tungsten ore, silica sands.

DOVE Spiral Concentrators are widely used in the closed circuits with ball mills, grading ore or gravity concentration, fine mud, metal beneficiation process, slurry particle size classification, sand ore and fine silt classification in the gravity dressing plants, dehydration, washing off mud and other operations.

FEATURES

- Economical & low maintenance, have no moving parts.

- High capacity, excellent metallurgical performance.

- Compact, modular units, save space and reduce capital costs.

- High grade and low-grade profiles with 3, 5 and 7 turn troughs.

- Assembles of single, twin or triple start units.

Specifications:

Feed size is usually between1.16 mm and 74 μm (14 and 200 mesh), but with iron ore, up to 2.3 mm (8 mesh) material may be treated to make a rougher concentrate, provided a high pulp density is used.

Solid content of approximately 15-35% solid concentration combined with wash water produces good results.

WARRANTY:

All DOVE equipment carry a standard Manufacturer’s Warranty, which can be extended to 5 years, in addition to lifetime spare parts supply service.

DOVE provides full technical services worldwide, including plant engineering design, mining site construction design, site assembly, installation, test run and training.

MANUFACTURING FACILITIES:

DOVE Equipment & Machinery manufacturing facilities are located about 30 minutes drive from the company Head office in Bangkok, which includes 8 factories and showroom.

DOVE Equipment and Machinery with over 50 years manufacturing expertise, and the largest range of mining and minerals processing technologies is the recipient of ISO 9001: 2015, Green Industry Certification, and Golden Eagle of Asia Awards 2020 Best Business of the Year (DOVE Equipment and Machinery and DOVE Instruments), which insures highest quality and standard of our manufacturing and customer service practices.

DOVE Manufacturing Facilities.

DOVE Equipment and Machinery 8 Factories.

Video of DOVE Manufacturing Facilities:

MINERAL TEST SERVICES:

DOVE laboratory will assay your ore samples rapidly and analyze your raw materials and recommend the most efficient processing plant according to the ore specifications, minerals composition, and ore assay results, and your project size and the geologic and topographic conditions of your mine.

Please, CONTACT US for your sample analysis and quotation.

WE HIGHLY RECOMMEND FORWARDING SOIL SAMPLES OF YOUR MINE TO US FOR ANALYSIS, IN ORDER TO DESIGN AND RECOMMEND THE MOST EFFICIENT PROCESSING PLANT, TAILOR MAID TO YOUR MINE REQUIREMENTS, FOR HIGHEST PRODUCTION RECOVERY.