JIG CONCENTRATORS

GRAVITY CONCENTRATORS

CAPACITY RANGE 3 TO 100 TONS/HOUR

Jig Concentrators are gravity concentration devices, designed and mainly used in mineral processing for washing, concentration, separation and recovery of coarse metals & minerals within the body ore, based on its specific gravity, over the selected screen mesh.

Since the high specific gravity differential of material makes good recoveries possible, use of Jig Concentrators to recover various metals and minerals is widely practiced within the industry.

Jig Concentrators have unique ability to absorb fluctuations in ore grades, tonnage rates and dilution, without any effect on recovery results. That makes them the most important and essential devices in mineral recovery.

High Performance & Ease of Operation

DOVE Jig Concentrators, batch type jigs, are designed to operate and simultaneously collect coarse production in a continuous mode, during the whole shift operating hours, without any frequent cleanups.

Automatic operation features and security-lock mechanism minimizes operator interference and provides you the capability to keep your production safe in field condition.

Low Environmental Impact

DOVE Jig Concentrators are completely environment-friendly gravity concentrators, which provide completely chemical or mercury-free operation, and operate with only clean or recycled water.

Quality Design

DOVE manufactures various models of fixed bed type Jig Concentrators, classified as the most advanced type in the industry. Jig Concentrators are fabricated with only high quality material and workmanship, unique features and price tag that are unmatched in the industry. DOVE Jig Concentrators are built to last.

FEATURES:

- Designed with duplex or quadruplex cells, Jig Concentrators ensure continuous and efficient washing, concentration, separation and recovery of metal & mineral production.

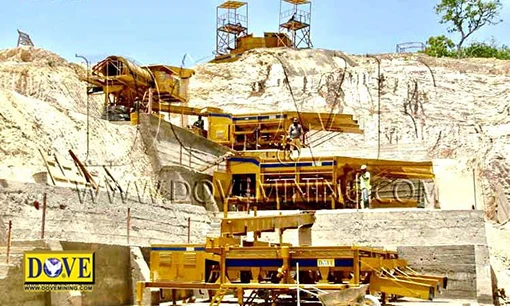

- Mounted on wheel set trailers, Jig Concentrators provide you the ease of rapid transportation to almost any location.

- Internal Hydraulic System allows you to regulate and control water pressure and flow, which effectively results in high recovery rates.

- Speed Control allows regulation of Jig Concentrators’ pulse, which effectively results in possibility to adjust and tune Jig Concentrators according to the capacity rate and material flow.

- Equipped with security system and locking mechanisms, Jig Concentrators provide you with safe operation at low supervision conditions, and prevent theft of the recovered production during the operating shift.

- Optional drive system: operate with diesel engines or electric motors.

APPLICATION OF JIG CONCENTRATORS:

Jig Concentrators are effectively used for the following mining applications:

- Washing, classification and concentration of coarse metal and mineral production from the ores, where metal and mineral grains are liberated. Recovery of metals and minerals of various kinds that occur in Alluvial (Placer) deposits.

- Recovery of Precious Metals, Precious and Semi-Precious Stones, Base Metals, Ferrous and Non-Ferrous Metals, Noble Metals, Heavy Metals.

- Applicable for Dredging Operations for river mining projects.

- Cobbing operations for primary (hard rock) deposits for waste discard, prior to final processing stages.

RANGE AND TECHNICAL SPECIFICATIONS:

| MODEL | NUMBER OF CELLS | CAPACITY | POWER REQUIREMENTS | ||

| SOLIDS | SLURRY | DIESEL DRIVE | ELECTRIC DRIVE | ||

| TPH | m3/HR | HP (kW) | HP (kW) | ||

| JS-100 | 2 | 3 – 4 | 9 – 12 | 7 (5.1) | 4 (3) |

| JS-150 | 2 | 5 – 8 | 15 – 24 | 7 (5.1) | 4 (3) |

| JS-200 | 2 | 8 – 10 | 24 – 30 | 7 (5.1) | 4 (3) |

| JS-300 | 2 | 20 – 30 | 60 – 90 | 8 (5.9) | 7.5 (5.5) |

| JS-320 | 2 | 30 – 40 | 90 – 120 | 8 (5.9) | 7.5 (5.5) |

| JS-350 | 2 | 40 – 50 | 120 – 150 | 10.5 (7.72) | 10 (7.5) |

| JS-400 | 4 | 60 – 80 | 180 – 240 | 2 x 10.5 (7.72) | 2 x 10 (7.5) |

| JS-460 | 4 | 80 – 100 | 240 – 300 | 2 x 10.5 (7.72) | 2 x 10 (7.5) |

* DOVE reserves the right to modify the specifications at anytime, without prior notice.

WARRANTY:

All DOVE equipment carry a standard Manufacturer’s Warranty, which can be extended to 5 years, in addition to lifetime spare parts supply service.

DOVE provides full technical services worldwide, including plant engineering design, mining site construction design, site assembly, installation, test run and training.

MANUFACTURING FACILITIES:

DOVE Equipment & Machinery manufacturing facilities are located about 30 minutes drive from the company Head office in Bangkok, which includes 8 factories and showroom.

DOVE Equipment and Machinery with over 60 years manufacturing expertise, and the largest range of mining and minerals processing technologies is the recipient of ISO 9001: 2015, Green Industry Certification, and Golden Eagle of Asia Awards 2020 Best Business of the Year (DOVE Equipment and Machinery and DOVE Instruments), which ensures highest quality and standard of our manufacturing and customer service practices.

DOVE Manufacturing Facilities.

DOVE Equipment and Machinery 8 Factories.

Video of DOVE Manufacturing Facilities:

MINERAL TEST SERVICES:

DOVE laboratory will assay your ore samples rapidly and analyze your raw materials and recommend the most efficient processing plant according to the ore specifications, minerals composition, and ore assay results, and your project size and the geologic and topographic conditions of your mine.

Please, CONTACT US for your sample analysis and quotation.

WE HIGHLY RECOMMEND FORWARDING SOIL SAMPLES OF YOUR MINE TO US FOR ANALYSIS, IN ORDER TO DESIGN AND RECOMMEND THE MOST EFFICIENT PROCESSING PLANT, TAILOR MAID TO YOUR MINE REQUIREMENTS, FOR HIGHEST PRODUCTION RECOVERY.