RIVERMINER®

DREDGING EQUIPMENT, GOLD DREDGE, DIAMOND DREDGE, FLOATING WASH PLANT FOR RIVER MINING

RIVERMINER® a union of Dredge and Floating Wash Plant, provides you with the most advanced, efficient and economical solution for simultaneous extraction, processing and recovery of gold, diamonds and other metals and minerals on board, with highest recovery and down to 40 microns (0.040 mm), (0.0016 inches) particle size.

UNIQUE FEATURES:

- RIVERMINER® is designed with full security system and locking mechanism to prevent the theft of production.

- RIVERMINER® Optional feature of extraction module eliminates the use of Divers.

- RIVERMINER® is supplied with capacity range of 100-2,800 m3/Hour (slurry). Each model of the RIVERMINER® can be upgraded with different components as client specific requirement and as specifications of the river.

- RIVERMINER® is designed for automatic, continuous and simultaneous extraction, processing and recovery of gold, diamond and other minerals on board, eliminates transport of material to shore for processing.

- RIVERMINER® eliminates the necessity for a processing plant extraction on shore, this feature results in faster processing time which results in higher production per day and also results in much better security of the production.

- RIVERMINER® is 100% environment-friendly, uses only recycled water, no toxic chemicals.

- RIVERMINER® provides higher returns of cash flow and production than any other dredging equipment in the market since RIVERMINER® is a combination of dredge and floating wash plant, and as a result is able to move rapidly on the river to mine and process the material continuously and efficiently much faster than the method of dredging and transporting of material on shore.

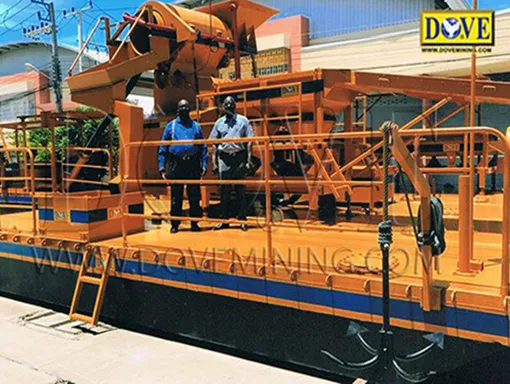

DOVE RIVERMINER® : production to field.

RIVERMINER® TECHNICAL SPECIFICATIONS (MINING GOLD)

| RIVERMINER® MODELS | PRODUCT DESCRIPTION | PROCESSING CAPACITY | ||||

|---|---|---|---|---|---|---|

| SOLIDS / HOUR | SLURRY / HOUR | |||||

| TONS PER HOUR | CUBIC METERS | CUBIC YARDS | ||||

| RM – 30/15G | RIVERMINER® GOLD PLANT | 30 | 100 | 130.7 | ||

| RM – 50/30G | RIVERMINER® GOLD PLANT | 50 | 300 | 392.3 | ||

| RM – 100/50G | RIVERMINER® GOLD PLANT | 100 | 500 | 653.9 | ||

| RM – 150/50G | RIVERMINER® GOLD PLANT | 150 | 500 | 653.9 | ||

| RM – 200/50G | RIVERMINER® GOLD PLANT | 200 | 700 | 915.5 | ||

| RM – 250/50G | RIVERMINER® GOLD PLANT | 250 | 800 | 1,046.3 | ||

| RM – 300/50G | RIVERMINER® GOLD PLANT | 300 | 1,000 | 1,307.9 | ||

| RM – 500/50G | RIVERMINER® GOLD PLANT | 500 | 1,000 | 1,307.9 | ||

NOTE:

- CONVERSION RATIO: ONE CUBIC METER (M3) IS EQUAL TO 1.30795 (YD3) CUBIC YARDS.

- SOLID CAPACITY IN THE SLURRY WILL BE BASED ON THE SAND & GRAVEL CONCENTRATION PER CUBIC OF SLURRY.

- CONTACT DOVE FOR LARGER CAPACITIES INFORMATION.

RIVERMINER® TECHNICAL SPECIFICATIONS (MINING DIAMONDS)

| RIVERMINER® MODELS | PRODUCT DESCRIPTION | PROCESSING CAPACITY | ||||

|---|---|---|---|---|---|---|

| SOLIDS / HOUR | SLURRY / HOUR | |||||

| TONS PER HOUR | CUBIC METERS | CUBIC YARDS | ||||

| RM – 30/15D | RIVERMINER® DIAMOND PLANT | 30 | 100 | 130.7 | ||

| RM – 50/30D | RIVERMINER® DIAMOND PLANT | 50 | 300 | 392.3 | ||

| RM – 100/50D | RIVERMINER® DIAMOND PLANT | 100 | 500 | 653.9 | ||

| RM – 150/50D | RIVERMINER® DIAMOND PLANT | 150 | 500 | 653.9 | ||

| RM – 200/50D | RIVERMINER® DIAMOND PLANT | 200 | 700 | 915.5 | ||

| RM – 250/50D | RIVERMINER® DIAMOND PLANT | 250 | 800 | 1,046.3 | ||

| RM – 300/50D | RIVERMINER® DIAMOND PLANT | 300 | 1,000 | 1,307.9 | ||

| RM – 500/50D | RIVERMINER® DIAMOND PLANT | 500 | 1,000 | 1,307.9 | ||

NOTE:

- CONVERSION RATIO: ONE CUBIC METER (M3) IS EQUAL TO 1.30795 (YD3) CUBIC YARDS.

- SOLID CAPACITY IN THE SLURRY WILL BE BASED ON THE SAND & GRAVEL CONCENTRATION PER CUBIC OF SLURRY.

- CONTACT DOVE FOR LARGER CAPACITIES INFORMATION.

RIVERMINER® TECHNICAL SPECIFICATIONS (MINING GOLD & DIAMONDS)

| RIVERMINER® MODELS | PRODUCT DESCRIPTION | CAPACITY | ||||

|---|---|---|---|---|---|---|

| SOLIDS / HOUR | SLURRY / HOUR | |||||

| TONS PER HOUR | CUBIC METERS | CUBIC YARDS | ||||

| RM – 30/15GD | RIVERMINER® GOLD & DIAMOND PLANT | 30 | 100 | 130.7 | ||

| RM – 50/30GD | RIVERMINER® GOLD & DIAMOND PLANT | 50 | 300 | 392.3 | ||

| RM – 100/50GD | RIVERMINER® GOLD & DIAMOND PLANT | 100 | 500 | 653.9 | ||

| RM – 150/50GD | RIVERMINER® GOLD & DIAMOND PLANT | 150 | 500 | 653.9 | ||

| RM – 200/50GD | RIVERMINER® GOLD & DIAMOND PLANT | 200 | 700 | 915.5 | ||

| RM – 250/50GD | RIVERMINER® GOLD & DIAMOND PLANT | 250 | 800 | 1,046.3 | ||

| RM – 300/50GD | RIVERMINER® GOLD & DIAMOND PLANT | 300 | 1,000 | 1,307.9 | ||

| RM – 500/50GD | RIVERMINER® GOLD & DIAMOND PLANT | 500 | 1,000 | 1,307.9 | ||

NOTE:

- CONVERSION RATIO: ONE CUBIC METER (M3) IS EQUAL TO 1.30795 (YD3) CUBIC YARDS.

- SOLID CAPACITY IN THE SLURRY WILL BE BASED ON THE SAND & GRAVEL CONCENTRATION PER CUBIC OF SLURRY.

- CONTACT DOVE FOR LARGER CAPACITIES INFORMATION.

WARRANTY:

All DOVE equipment carry a standard Manufacturer’s Warranty, which can be extended to 5 years, in addition to lifetime spare parts supply service.

DOVE provides full technical services worldwide, including plant engineering design, mining site construction design, site assembly, installation, test run and training.

MANUFACTURING FACILITIES:

DOVE Equipment & Machinery manufacturing facilities are located about 30 minutes drive from the company Head office in Bangkok, which includes 8 factories and showroom.

DOVE Equipment and Machinery with over 60 years manufacturing expertise, and the largest range of mining and minerals processing technologies is the recipient of ISO 9001: 2015, Green Industry Certification, and Golden Eagle of Asia Awards 2020 Best Business of the Year (DOVE Equipment and Machinery and DOVE Instruments), which ensures highest quality and standard of our manufacturing and customer service practices.

DOVE Manufacturing Facilities.

DOVE Equipment and Machinery 8 Factories.

Video of DOVE Manufacturing Facilities:

MINERAL TEST SERVICES:

DOVE laboratory will assay your ore samples rapidly and analyze your raw materials and recommend the most efficient processing plant according to the ore specifications, minerals composition, and ore assay results, and your project size and the geologic and topographic conditions of your mine.

Please, CONTACT US for your sample analysis and quotation.

WE HIGHLY RECOMMEND FORWARDING SOIL SAMPLES OF YOUR MINE TO US FOR ANALYSIS, IN ORDER TO DESIGN AND RECOMMEND THE MOST EFFICIENT PROCESSING PLANT, TAILOR MAID TO YOUR MINE REQUIREMENTS, FOR HIGHEST PRODUCTION RECOVERY.